Technological lines

The type and scope of machines used in the technological line, depends on the client’s needs. The machines are selected during initial discussions with client, therefore we have the opportunity to offer an optimal solutions. By using the 3D software we prepare a preliminary spatial model of the technological line. In the next stage our designers make the line layout in the CAD program.

During municipal or industrial waste processing, we use our own machines, which allow us for appropriate classification and segregation of materials from the waste fraction.

WE OFFER:

Refuse derived fuels processing lines

In RDF processing lines, in addition to the conveyors, the main elements are shredders and air, magnetic or disk separators. The selection of size and capacity of individual types of applied machines, depends on the type of used raw material placed on the line. During selection of production line components, it is key task to correct assess the composition of the waste stream.

Air separation lines (balistic)

The air separators are assembled in lines, which use air flow for waste segregation. The separators, which we produce are adapted to the client’s requirements and available work space. A properly adjusted separator allows to achieve the expected effect, which is the segregation of heavy fraction from the stream of preliminary fragmented wastes.

Optical scanning lines

The optical scanners are applied in the lines, which use optical waste scanning technology. In order to spread the material on the belt according to the optical scanning proccess needs, we use accelerating conveyors made by us, with a belt width up to 3 m. The second important element of the line is the expansion chamber, which segregate the previously separated materials.

Construction waste sorting line

The main task of the construction waste sorting line is separation of heavy fractions (i.e. debris) from other impurities as foils, wood, metals or styrofoam. After separation of the heavy elements, the material is sorted in a waste screen. The basic segregation of lightweight waste can take place mechanically, by using ballistic separation or by using air flow. There can be applied also manually segregation in a sorting cabin.

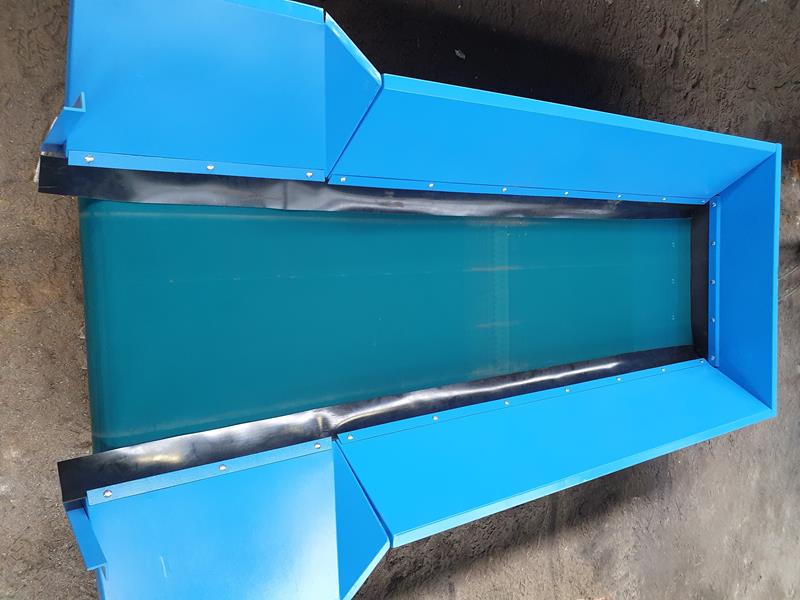

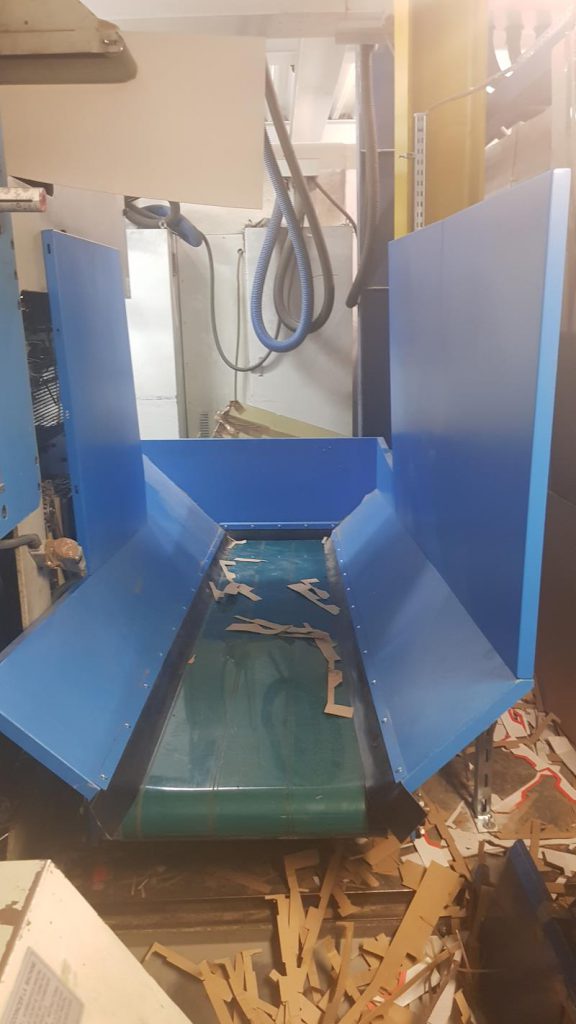

Conveyors with PCV belts dedicated for plants producing cardboard's package

The leftovers created at the end of production lines in industrial installations of campanies producing cardboard’s package, have the form of cutted waste or larger cardboard pieces. In these lines except for pneumatic solutions, the lightweight conveyors with PCV belts are used for waste transportation.

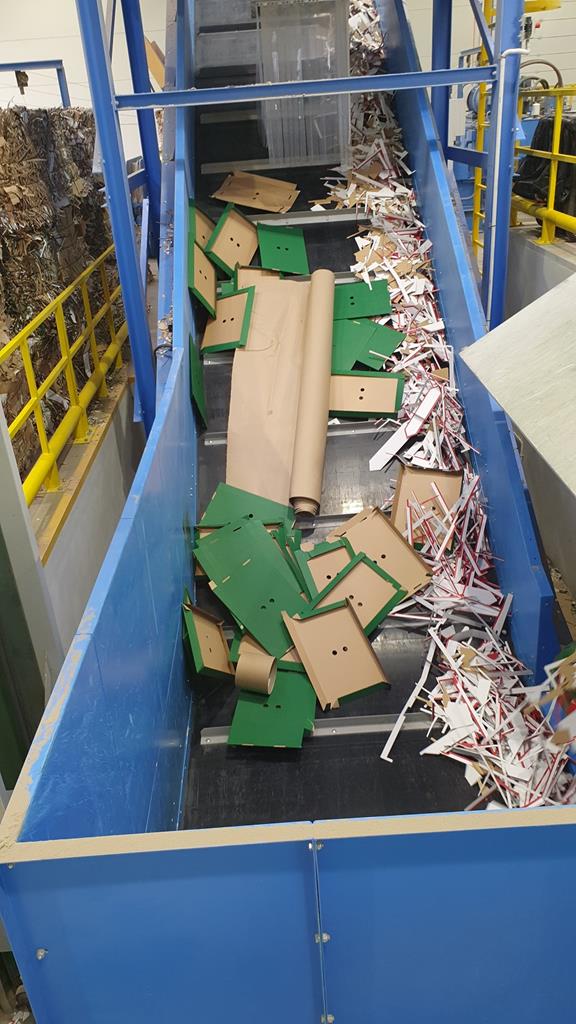

The waste transport lines for channel presses

In many waste processing plants or producing cardboard packaging, one of the last production stages is the transport of waste to channel presses. Loading of material into channel presses is usually carried out by means of a chain or roller conveyor belts, whose shape and width are adapted to the size of the feeding hole in the press. Additionally, there can be use a chute as a complementary element between the conveyor and the press, which can be made also with an emergency dump flap.

Processing lines with magnetic separators

The magnetic separators for sorting of metal waste are use in some installations with belt conveyors. In the case of installing such a separator in the technological line, it is important to select the proper kind of it, depending on transported fraction. In addition, the conveyor shall be designed in such a way, that its able to work with the applied magnetic separator.

Compost sifting lines

The fraction, which goes to a composting plant and was formed in the process of municipal waste segregation still may have an unwanted composition. It depends on the preliminary apllied segregation process. Drum screens, air separators and roller conveyors are the basic components used in these lines to improve the composition of the compost.

Compost systems

One of the possible composting system is heap composting. This process can take place in an open area or inside the building. In both cases, a hydraulic rewinder of a heap’s covering can be used. It much helps with the large-size membranes operation.