About us

We are the manufacturer of special machinery and provider of technology for the recycling industry,

in particular for the processing and transport of municipal and industrial waste.

With over 15 years of experience in this field, we want to base our activities on two components:

- experience gained while using our own lines for waste segregation, production of alternative fuels as well as composting plants,

- practical knowledge related to the process of designing and manufacturing of machines for the recycling industry and municipal waste economy.

Our offer is dedicated to companies interested in waste processing systems. We will advise, what solutions will be the best for you in the field of industry, which is waste recycling.

We offer machines and technological lines tailored to the individual needs of each customer. Proven technology let us to produce an equipment, whose quality meets the high requirements of our clients.

We focus on continuous development, which is the reason why we are constantly looking for new ideas and introduce new solutions making our mchines even more functional. Our goal is, that each customer who will be the user of our machines, would be satisfied with them during many years.

We provide:

- Design of machines and constructions

- 3D design of technological lines

- Development of technological projects and solutions

- Manufacture and asse mbly of machines

- Control and automatics systems

Our implementations

Machines

Air ballistic separators

Chain conveyors – strengthen version

Chain conveyors – light version

They are made with using the lighter construction version. This type of machine allows for very stable transport of lightweight fractions such as plastics or alternative fuels RDF.

In comparison to conveyors with rollers, they provide much greater operational reliability and the maintenance-free.

Chain conveyors – banana shape version

Sliding coveyors

Accelerating conveyors

Roller conveyors

Mobile conveyors

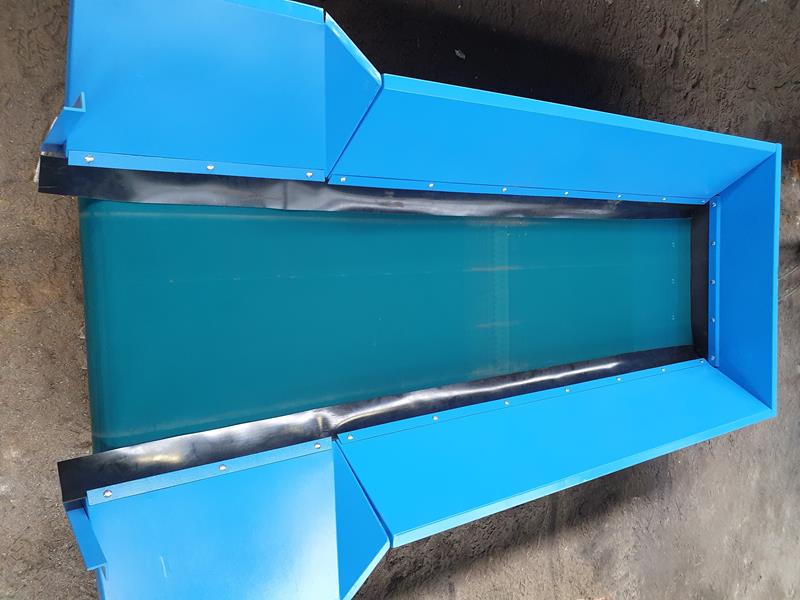

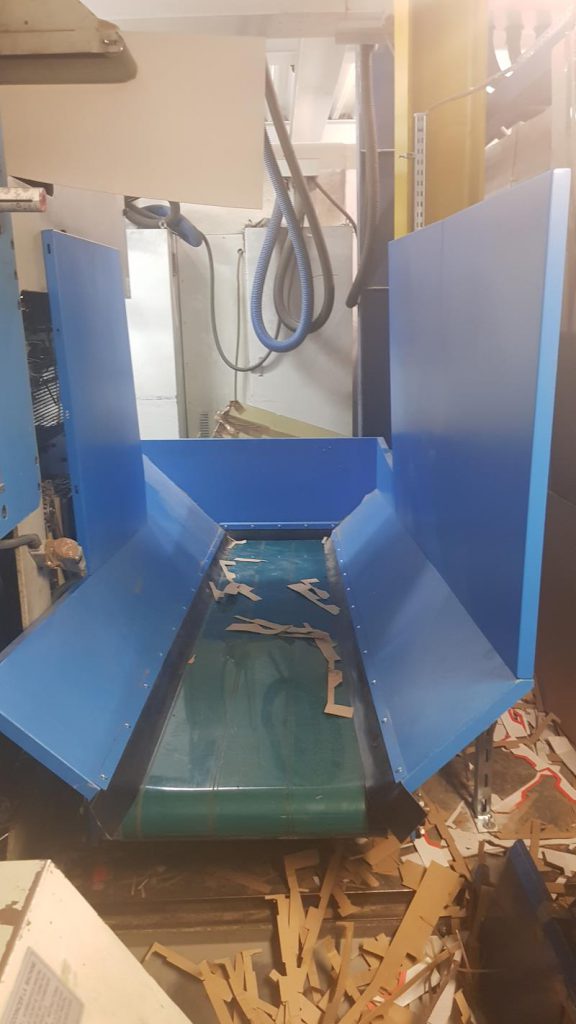

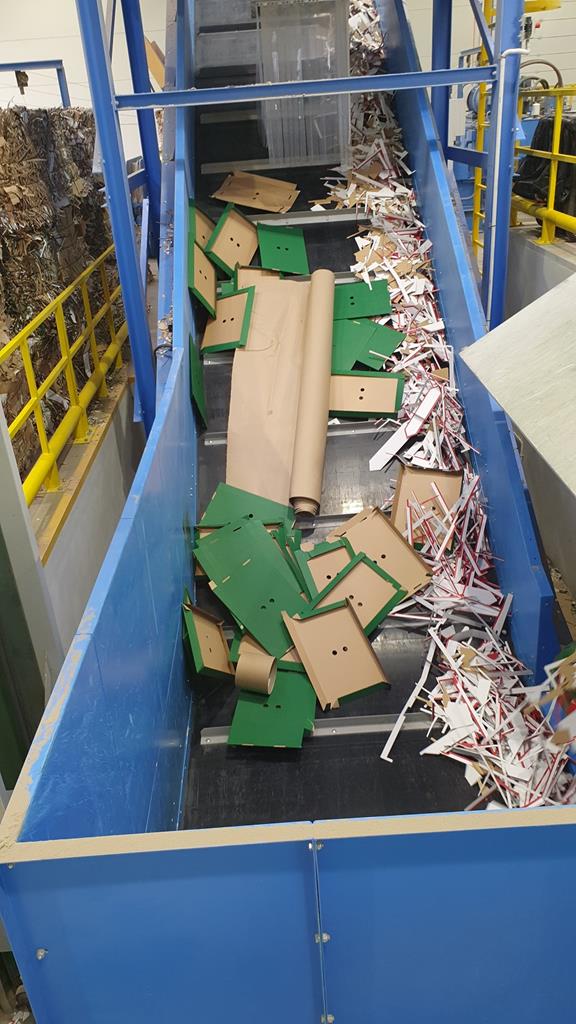

Conveyors with PCV belt

Ballistic separators

Sorting screen drum

Membrane rolling machine

Technological lines

WE OFFER:

Refuse derived fuels processing lines

Air separation lines (balistic)

Optical scanning lines

Construction waste sorting line

Conveyors with PCV belts dedicated for plants producing cardboard's package

The waste transport lines for channel presses

Processing lines with magnetic separators

Compost sifting lines

Compost systems

Production and Service

PRODUCTION

The production process of each machine or construction begins with preparing of drawing documentation. On it’s basis there can be started the manufacturing process.

To the production of machines, we use usually an elements cutted by a laser cutting tools and bent by folding brake. Manufacturing of supporting structures or machine frames is an additional scope made in our workshop.

SERVICE

Supplier’s warranty service is valid during agreed time after the commissioning of each installation to the purchaser. We are able to offer our post-warranty service, too.

Our goal is to offer our customers the support with servicing and maintenance of machines or entire installations.

Examples of components, which can be provided by our service:

- conveyor drums

- conveyor chains and rollers

- sorting drums

- sieve plates for sorting drums

- consumables of ballistic separators

- No categories

Recent Comments